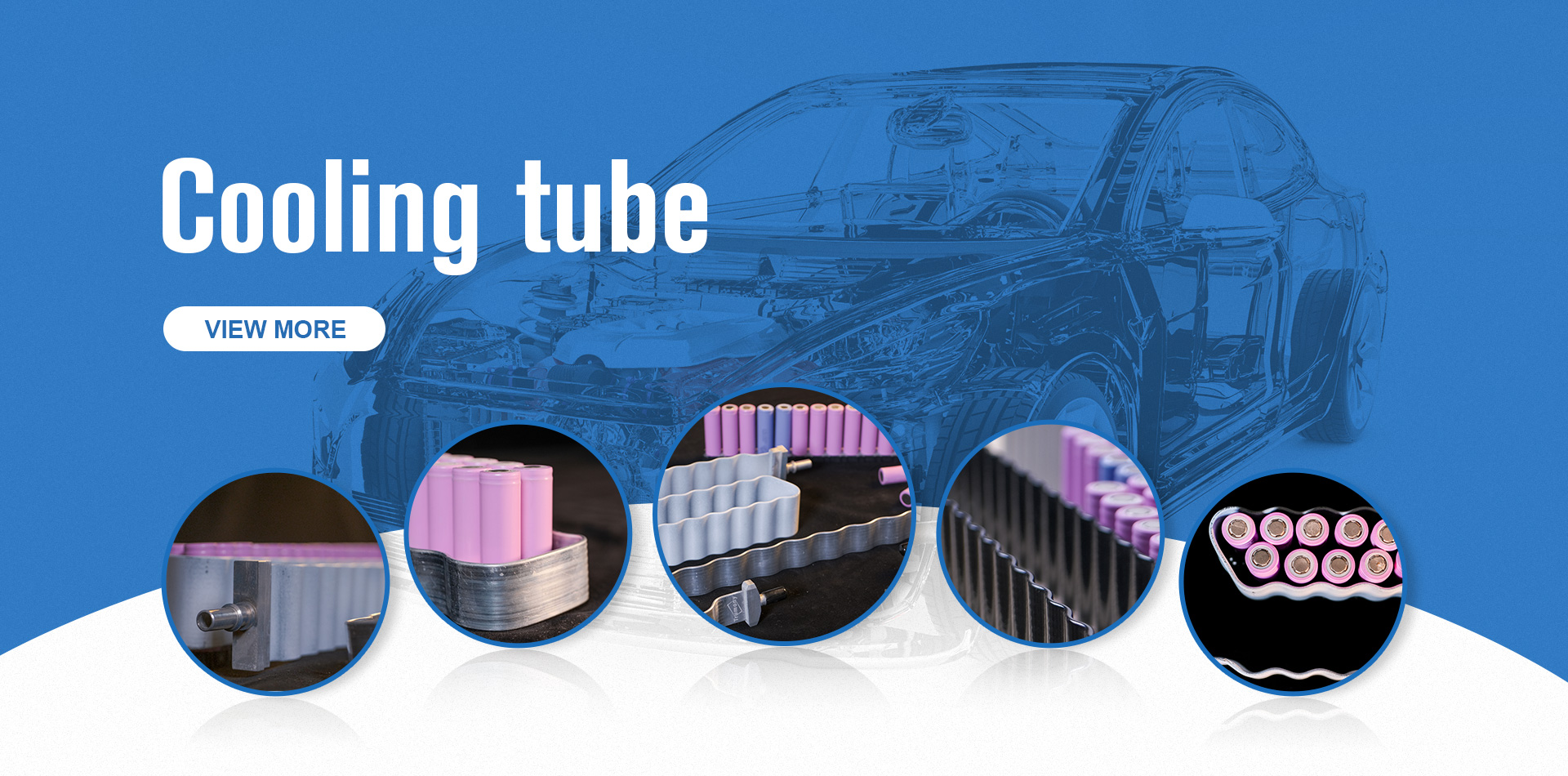

Serpentine Heat Exchanger Cooling Ribbon for Electric Vehicle

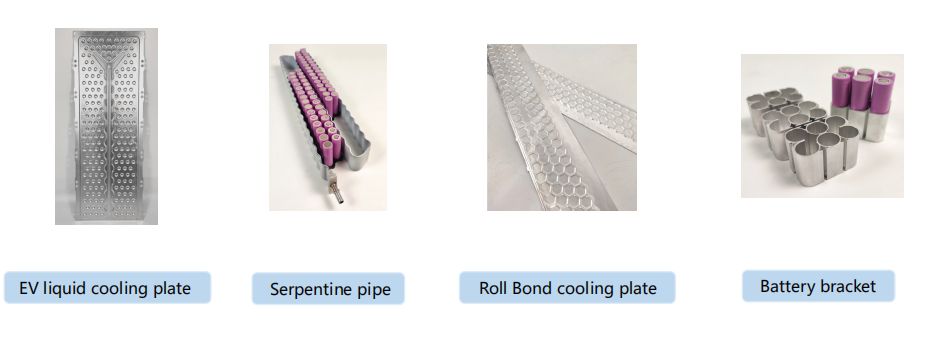

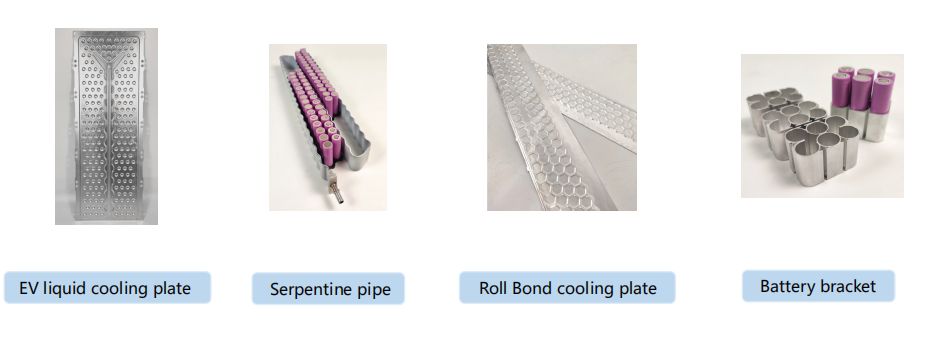

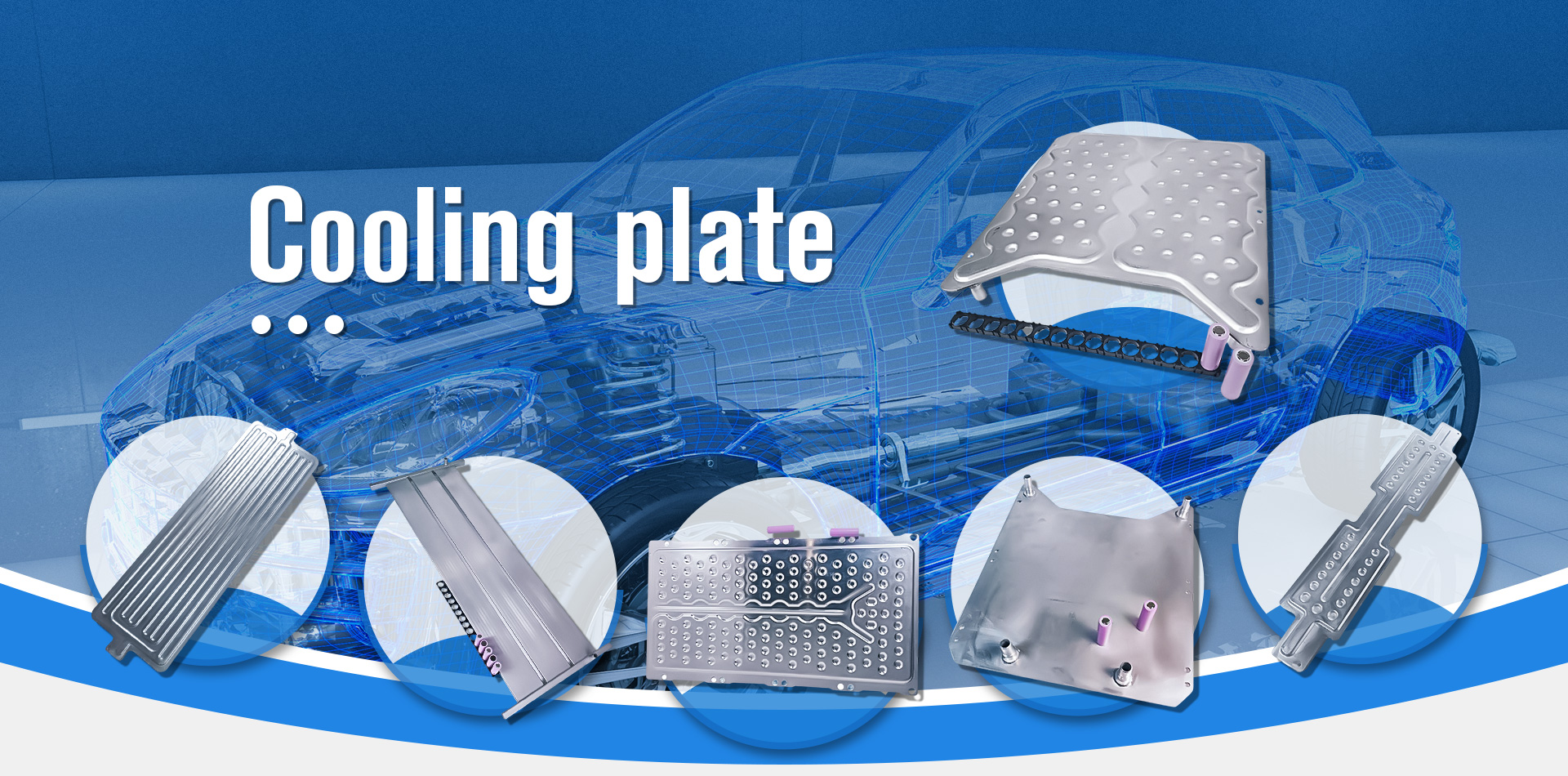

The role of cooling plate is to keep maximum lithium-ion battery and optimum performance. Trumony is aluminum manufacturer, it's one of our biggest advantages to provide aluminum based cooling components for EV battery. We have strict quality control system with certificated TS 16949. As rich experienced and good communication, we have good reputation in clients.

From wavy shape/U shape/braze to test as an integration, fully automated informatization and flexible production could be achieved.

The open mold service and subsequent volume production are easily accessible. We have served many domestic and abroad clients in the automobile and energy storage industry.

Features:

*Design options:

1) Stamping type cold plate

It used for prismatic cells and battery pack, bottom & side cooling solution;

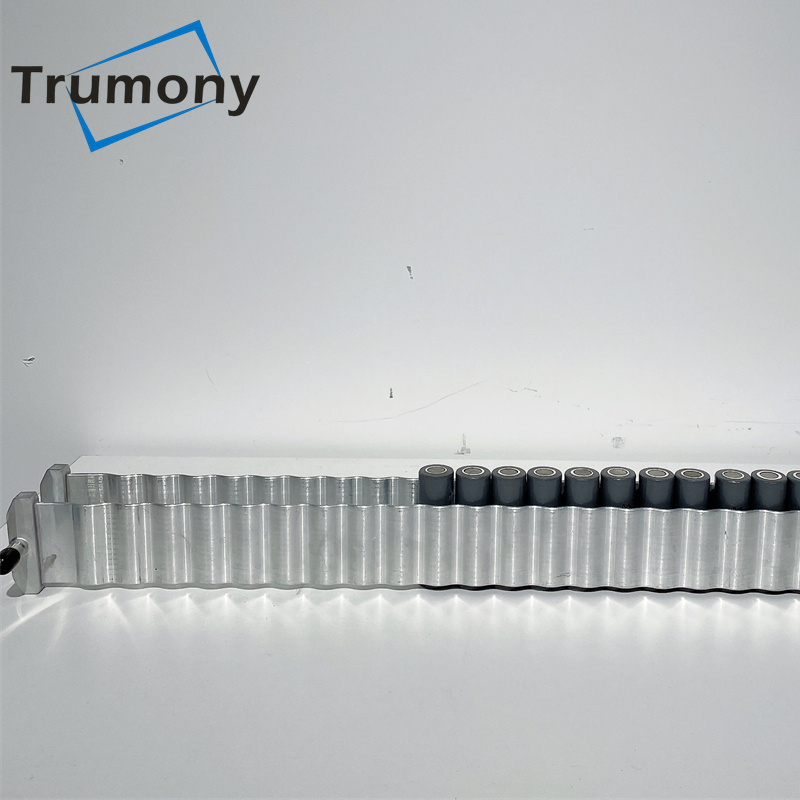

2) Serpentine cooling ribbon

Applied for cylindrical cells: 18650, 21700, 3270, 4680 and etc;

3) Micro-channel tube with manifold

For battery pack side or bottom battery cooling;

4) Roll bonding cooling plate;

5) Friction stir welding plate

It has a simpler welding process, higher production efficiency, higher weld strength, and can avoid problems such as pores and liquid leakage in high-temperature fusion welding.

* Customized plate size and flow channel path

1) Design your liquid cooling plate according to battery pack boundary size;

2) Optimization flow path as the result of flow field simulation;

* One-stop service package

1) Design service: thermal simulation, flow field simulation, prototype making;

2) Online meeting technical support;

3) Sample fast dispatch.

Facility:

1. Cold rolling production line

2. Foil rolling line

3. Other auxiliary equipment

4. Color coating production line

5. Embossed aluminum production line

6. Carbon production line

7. CNC center

FAQ

Q: What kind of battery cold plate can you provide?

A:

1) Stamped cooling plate for prismatic cells / battery pack.

2) Serpentine tube for cylindrical cells, such as 21700, 18650, 3270, 4680 big cell.

3) Extruded tube with manifold for soft battery pack.

4) Roll bond cooling plate for heating / cooling...

Q: What method of processing technology?

A: We have brazing line, stamping line, extrusion line, and roll boned process line. Also CNC centre is available.

Q: If we don't have design, can you assist in design?

A: Yes, we can! We have a strong and experienced design team. Flow path design, thermal simulation, mechanical simulation and design optimation are support. Kindly share with us your detail project, we'd love to do DFM for you.

Q: How fast you can make prototype?

A: About 3~5wks. The precise lead time will depends on your design and producing process.

# Aluminum Water Cooling Plate, Cooling Tube For ESS, snake tube for ESS, Snake Tube For ESS,Heat Exchanger Components

Product Categories : Liquid Cooling Components For EV > Cooling Ribbon

Inquiry Basket (

Inquiry Basket (

Scan to visit

Scan to visit